Quality is very difficult to characterize, and it is basically expressed: “Fit for use or purpose.” It is all about addressing the necessities and assumptions of clients with keeping in mind it’s usefulness, functionality, design, reliability, and cost of the item.

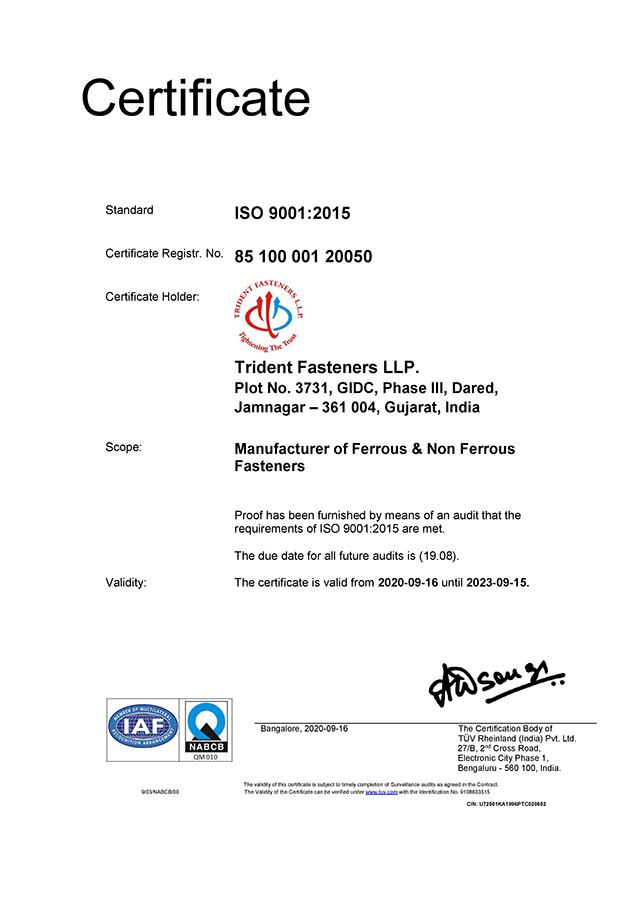

At Inox Trident Fasteners, we believe that “Quality is not act. It is a habit.” Therefore, with a tremendous experience of more than a decade in addition with ISO 9001:2015 Certification, we focused on manufacturing all types of fasteners and its application and alloys like Copper, Brass, Silicon Bronze, Phosphorus Bronze, Carbon Steel and Stainless Steel. We incorporate the best testing procedures with international quality standards like DIN, ISO, ASTM, IS, BS etc. to analyze and give a quantitative analysis of products with supportive evidence in form of elaborate test results.

Our Lab is NABL ISO/IEC 17025:2005 certified, which facilitates in keeping up with consistent excellency. The fasteners go through severe quality checks at each checkpoints to accomplish greatest quality control for each assembling interaction. Our inspection facilities are outfitted with best in class machineries for testing of both physical and metallurgical parts of fasteners for the most demanding industries. All of these tests are conducted under the supervision of our professional work force who make sure that everything is in compliance with the Quality Assurance System set up across departments.

Our Certificates